Description

Equivalent to well-known brand product 577 – Yellow

Pipe Seal Adhesive with Approvals A2577 is used in the sealing of all types of threaded connections against water, oil, gases and most common materials conveyed by metal pipes. It is used on most hydraulic, pneumatic, oil, water and gas connections. This is a medium strength pipe-sealant which provides a non-shrink, instant, low-pressure seal on tightened fittings.

Non-hazardous

Unlike most pipe seal sealants this is produced from the latest non-hazardous technology, so there are no hazard symbols or risk and safety phrases for this product. This pipe seal can comply with even the most stringent health and safety requirements.

Curing information

Pipe seal A2577 is a high-viscosity thixotropic gel paste which cures rapidly, sealing instantly to 10,000 psi (689 bar) through its anaerobic cure system in contact with metals in the absence of air (oxygen).

When cure speed is extended due to low temperatures or inactive surfaces, an activator can be used. The best results are found if A2577 is applied to a second or third thread form.

Once fully cured this pipe seal can resist pressures of up to 10,000psi, whilst maintaining a vibration proof seal that is resistant to most chemicals and corrosion.

Pipe Seal Adhesive with Approvals – 250ml – A2577 Application Uses

This Pipe Seal Adhesive with Approvals – 250ml – A2577 – is ideal for many application uses on metal and metal fixings, including, for instance:

Sealing Household Water Pipes

You can use these Pipe Seal Adhesive with Approvals – 250ml – A2577 to create a reliable, watertight bond on standard household water lines, such as sinks and washing machines – which helps prevent leaks and costly water damage from occurring.

Repairing Central Heating Systems

Applying this adhesive to central heating pipes can also improve their overall efficiency by reducing the risk of leaks and corrosion, so you can enjoy a cosy home throughout the colder months.

Securing Irrigation Systems

Whether you have a simple garden hose or a more complex sprinkler setup, Pipe Seal Adhesive A2577 will give you solid connections that keep your plants hydrated without wasting water in the process.

Fixing Garden Hose Fittings

As you know, frequent twisting and turning of garden hoses can loosen connections over time, there is where a small amount of adhesive helps reinforce these joints, ensuring they remain drip-free.

Maintaining Marine Plumbing

Boat and yacht owners can also use Pipe Seal Adhesive to safeguard onboard water and fuel lines against constant motion and challenging marine conditions for extra peace of mind.

Reinforcing Air Compressor Lines

You can also help to prevent air leaks in your workshop or garage by applying the adhesive on air compressor fittings. Which in turn will help maintain consistent pressure and improve tool performance.

Ensuring Secure Gas Connections

Thanks to its strong and safe formulation, Pipe Seal Adhesive A2577 is suitable for sealing gas lines, helping you to minimise the chances of dangerous leaks in your home or workplace occurring.

Supporting Automotive Repairs

From coolant lines to vacuum hoses, this adhesive can help you fix or reinforce various components in cars, trucks, and other vehicles, giving you more reliability on the road as a result.

Protecting Industrial Piping

Factories and production facilities often deal with high-pressure systems. That is where this Pipe Seal Adhesive gives you a professional-grade seal to keep everything running smoothly and efficiently for you.

Securing Drainage Systems

A2577 can also be applied to residential or commercial drainage pipes, giving you a long-lasting seal that prevents unpleasant odours and reduces the risk of structural damage rom occuring as well.

Not suitable for oxygen systems

Please note, that A2577 is not suitable for oxygen systems.

Excess

Any excess can be simply wiped away, any migration into lines will not solidify and can be flushed away during commissioning.

Gas & Water Approval

This pipe sealant has gas (BSEN751/DVGW) and water (WRAS) approvals for use on pipe fittings and course threaded components.

Application uses

This pipe seal adhesive is widely used in sealing threaded connections against:

- Water

- Oil

- Gases

- Most common materials conveyed by pipes

Known as

This pipe seal adhesive is also known as:

- Pipe Seal with approvals

- WRAS approved pipe seal

- BSEN751 approved pipe seal

- Fast cure pipe seal

- High pressure pipe seal

- Pipeseal or pipe seal

- DVGW approved pipe seal

Adhesive technical information

| Colour | Yellow |

|---|---|

| Chemical form | Dimethacrylate ester |

| Cure | Anaerobic |

| Secondary cure | Activator |

| Components | Single – requires no mixing |

| Viscosity | Thixotropic, high |

| Strength | Medium |

| Application | Thread sealing |

Adhesive typical properties of cured material

| Pressure resistance | 10,000 psi |

|---|---|

| Temperature range | -53°C to 148°C |

| Breakaway torque M10 steel bolts and nuts ISO 10964 | 11Nm |

| Prevail torque M10 steel bolts and nuts ISO 10964 | 6Nm |

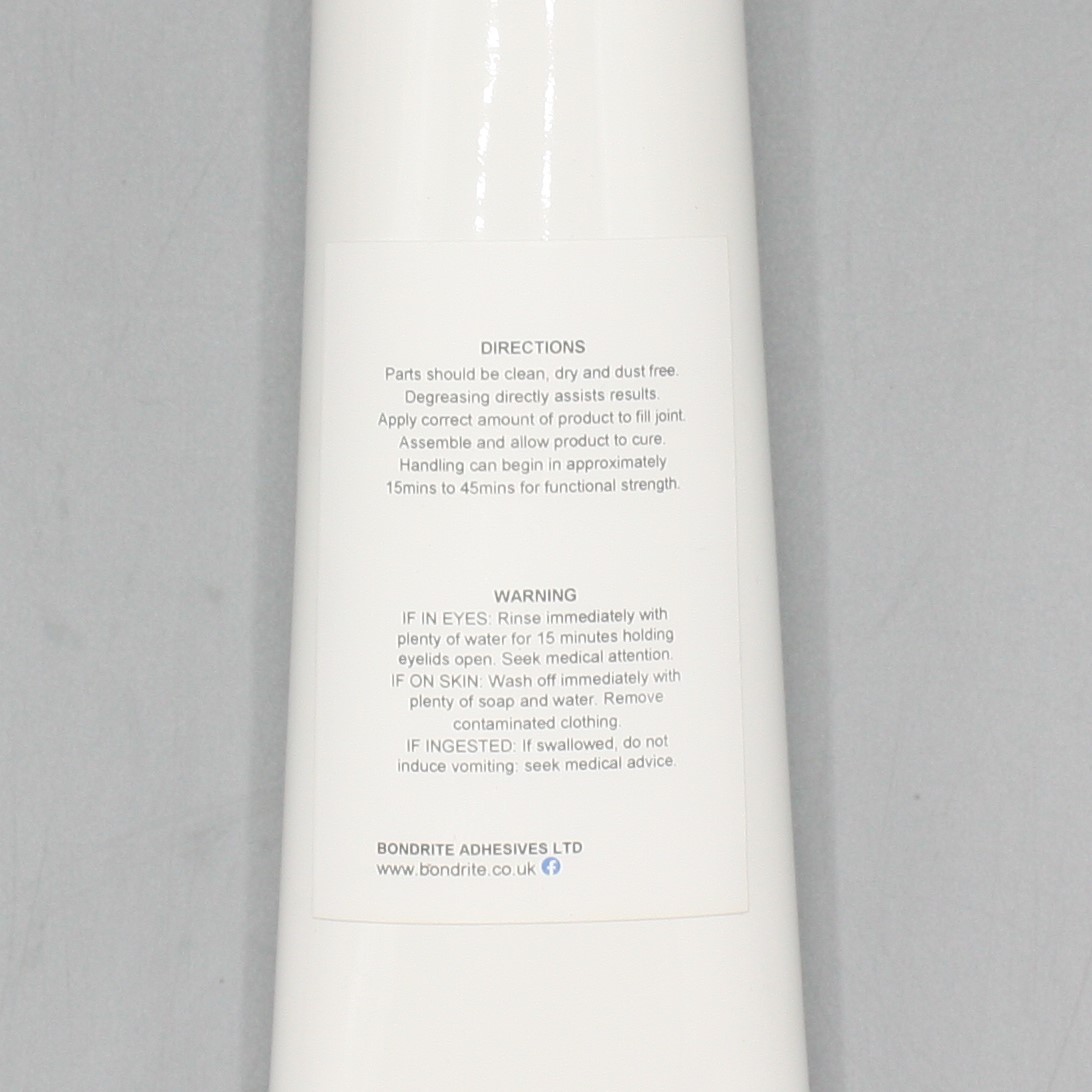

Directions for use

- For optimum performance surfaces should be clean and free of grease (internal and external).

- If the material is an inactive metal consider using an activator.

- Shake the product thoroughly before use.

- Apply the product to the male fitting on the leading threads in a 360º bead, leave the first thread free, making sure all voids are full. For bigger threads apply more product accordingly and putting a bead on the female.

- Assemble and tighten as required.

- Properly tightened fittings will seal to moderate pressures instantly. For maximum resistance allow a minimum of 24 hours to cure.

Disassembly information

- Remove with standard hand tools.

- In circumstances where hand tools do not work, use localized heat to bolt or nut, disassemble while hot.

Cleaning information

To remove cured adhesive please use a combination of solvent and abrasion such as a wire brush.

Precautionary information

- Do not try to remove forcibly.

- If adhesive gets into eye, keep eye open and rinse thoroughly. Seek medical attention.

- Keep well out of reach of children.

Storage information

Keep adhesive in a cool, dry place out of direct sunlight. To prevent contamination of unused material, do not return any adhesive to its original container. For specific shelf-life information, contact us.

Pipe seal adhesive price

If you buy this Pipeseal Adhesive in bulk we offer a discounted rate making it even better value for money.

Not sure if this pipe sealant is right for your requirements?

If you are not sure if this adhesive is correct for your requirements, please contact us to discuss your requirements and we can point you in the right direction.

Reviews

There are no reviews yet.