Description

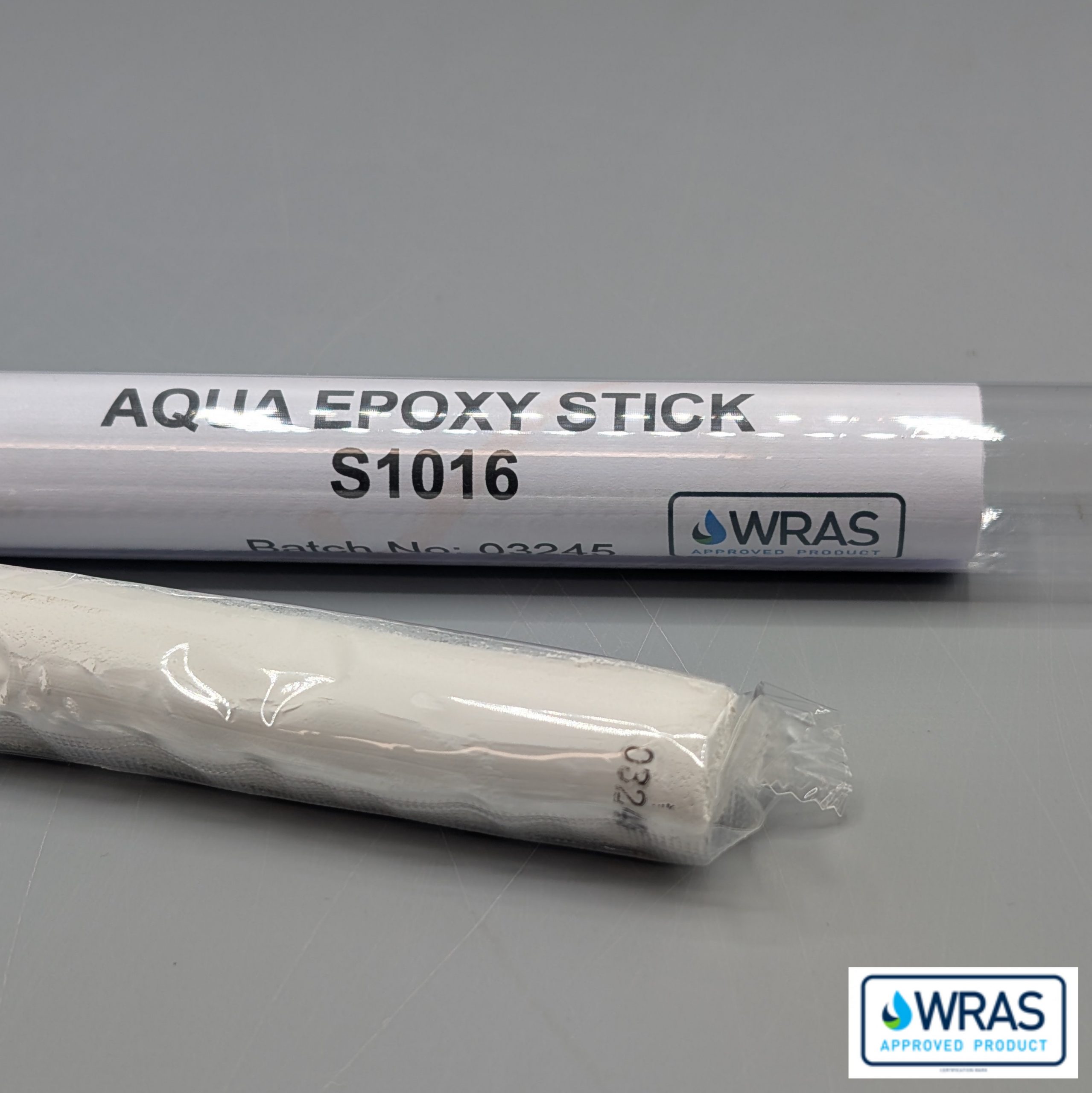

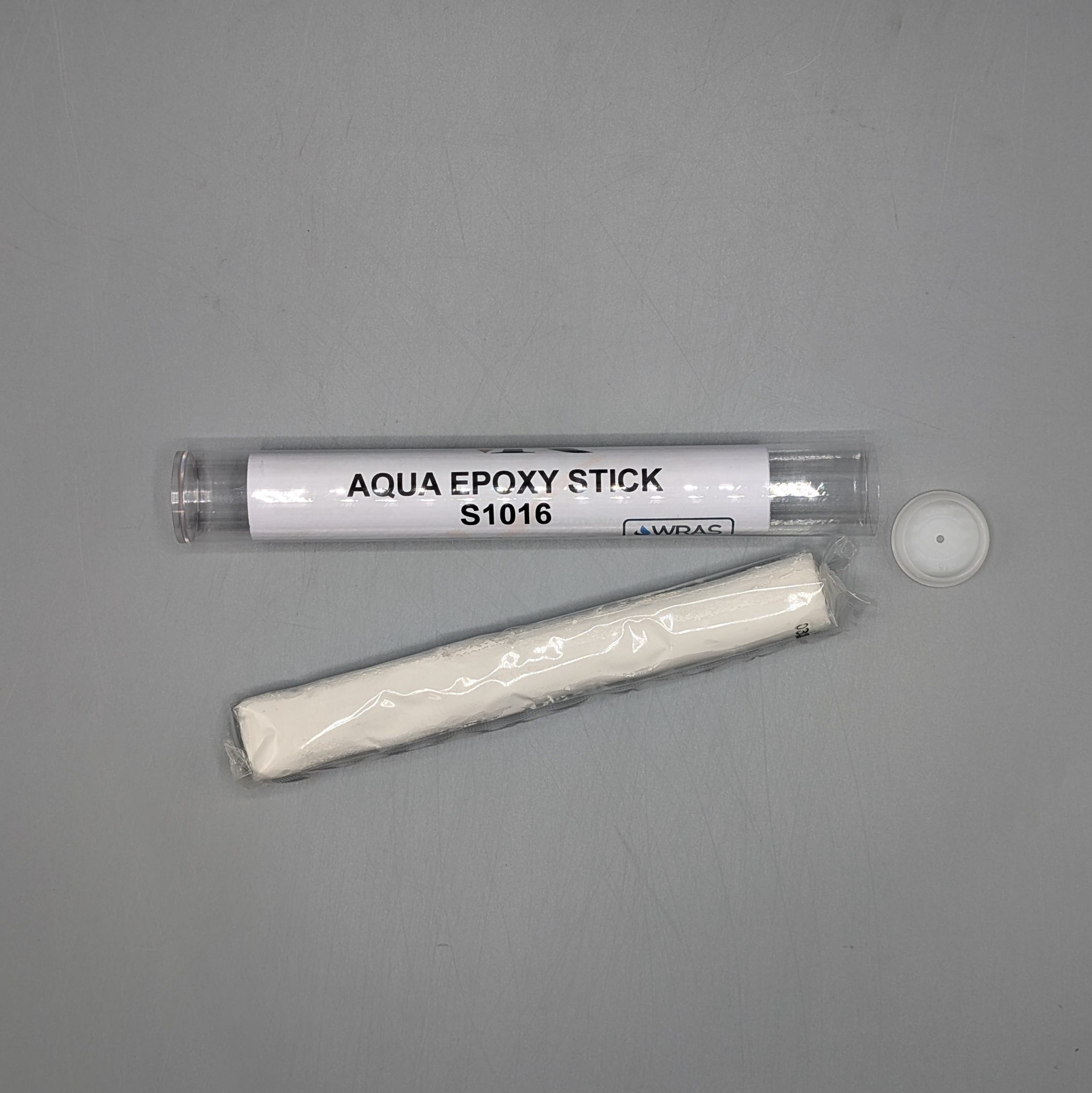

Aqua Epoxy Putty Stick, S1016, is a hand-kneadable, epoxy putty used to provide permanent repairs in damp, wet or underwater applications. It may be applied underwater, and it will bond tenaciously to substances such as fibreglass, metal, wood, concrete and ceramics. Our sticks are great value as they are approximately 114g, 175mm long and 22mm diameter which is larger than most on the market. Aqua epoxy stick has WRAS approval, meaning it is certified as safe to use on pipes and fittings carrying drinking water.

This putty aqua stick comes in a handy rod form with the curing agent encapsulated in the base material. Its putty-like consistency eliminates drips and runs, providing “no mess” application with no tools required to use. It can be used in both salt water and fresh water conditions.

Colour

This putty is white in colour after use.

Application uses

After proper mixing, S1016 moulds like clay and may be used in many industrial and home maintenance applications, including:

- Repair of iron pipes

- Tanks

- Tools and equipment

- Repair blow holes

- Holding and placement of fixtures and signs

- Repair cracked castings

- Repairs to down spouts and gutters

- Repairs to duct-work

- As well as countless other uses

Metal Repair

Aqua Epoxy Stick S1016 is ideal for repairing metal components such as steel pipes, tanks, and machinery that are partially or wholly submerged.

Its high-strength bonding properties ensure durable repairs, making it suitable for industrial applications where structural integrity is crucial. Whether it’s fixing cracks, holes, or worn-out parts, this epoxy stick provides a reliable solution, minimizing downtime and maintenance costs.

Plumbing Fixes

Aqua Epoxy Stick S1016 is an effective solution for repairing leaks and cracks in metal and ceramic pipes, fittings, and fixtures.

Its waterproof properties ensure secure seals, preventing water damage and corrosion.

Whether used in residential, commercial, or industrial plumbing systems, this epoxy stick provides a durable and cost-effective repair solution, prolonging the lifespan of plumbing infrastructure and minimizing maintenance requirements.

As it has WRAS approval it can be used on Potable water systems.

Marine Maintenance

In the marine industry, Aqua Epoxy Stick S1016 is utilised for repairing hulls, propellers, and other components exposed to harsh marine environments. It can even be applied under the water line.

Its resistance to saltwater, chemicals, and UV radiation makes it well-suited for marine applications, ensuring reliable repairs that withstand corrosion and erosion.

This enhances vessel safety and longevity, reducing the need for frequent repairs and replacements, thus lowering operational costs.

Outdoor or Submerged Infrastructure Repairs

For outdoor infrastructure like bridges, fences, and pipelines, Aqua Epoxy Stick S1016 offers a durable solution for repairing structures exposed to or submerged in water.

Its weather-resistant properties protect against corrosion, erosion, and temperature fluctuations, ensuring long-lasting repairs that withstand harsh outdoor conditions.

This application enhances infrastructure resilience and longevity, reducing maintenance requirements and enhancing safety.

DIY Home Repairs

Aqua Epoxy Stick S1016 is a versatile tool for DIY enthusiasts tackling various repair projects around the home, from fixing garden tools and outdoor fixtures to patching up water barrels and other containers.

Its ease of use, quick curing time, and strong adhesion properties make it suitable for amateur repair tasks, providing a cost-effective alternative to professional services.

This empowers homeowners to undertake repairs themselves, saving time and money while maintaining household functionality.

Remain stable for years

The unused portion of S1016 will remain stable for years if protected from direct contact with the air, in cool conditions.

Technical data

| Work life | 5 minutes @ 20°C |

|---|---|

| Resistant to | Hydrocarbons, ketones, esters, halocarbons, alcohols, aqueous salt solutions and dilute acids and bases. |

| Electrical Resistance | 30,000 mega Ohms |

| Shelf life | >18 months @ 25°C |

Directions for Use

Mixing

Twist or cut off required amount. To mix, knead with fingers to a uniformed colour. If mixing is difficult, warm to room temperature or slightly above. Apply to the surface to be repaired (within 2 minutes of mixing). The mixed epoxy does not exhibit high bond strength at this point, but appears to be merely lying on the surface. Force into any cracks or holes to be filled and strike off excess material. Work the material forcefully into the surface and apply pressure until adhesion begins to take effect.

For a smooth appearance of the cured compound, hand rub with water or a damp cloth prior to hardening.

Hardening

Remove excess material before hardening begins. After 15-20 minutes, the epoxy will harden like metal and start to form a tenacious bond. After just 60 minutes, it is completely cured and can be drilled, sawed, carved, sanded, stained or painted.

In order to achieve optimum adhesion, surface should be cleaned free of grease or dirt. Scuffing or sanding the surface prior to cleaning helps to ensure a good bond.

Cure Performance

| Initial cure | 1 hour max |

|---|---|

| Full cure time | 24 hours |

| Lap shear strength (steel) | 6.2 N/mm2 |

| Shore D hardness | 96 |

| Compressive strength | 83 MPa |

Properties

| Approvals | WRAS |

|---|---|

| Max. temperature resistance | 120°C continuous | 150°C intermittent |

Precaution

IRRITANT: Contains epoxy resin and may cause skin irritation in sensitive individuals. Unnecessary skin contact should therefore be avoided. If skin contact occurs, wash with a proprietary hand cleaner, followed by washing with soap and water. In case of eye contact, flush with clean water for at least 15 minutes, then seek medical attention. When fully cured, the product can be considered non-toxic. Store in cool conditions, preferably away from direct sunlight or excessive heat. Shelf life at least 18 months @ 25°C.

Aqua Epoxy Stick adhesive price

If you buy this adhesive putty in bulk we offer a discounted rate making it even better value for money.

Not sure if this aqua putty is right for your requirements?

If you are not sure if this adhesive is correct for your requirements please contact us to discuss your requirements and we can point you in the right direction.

Reviews

There are no reviews yet.