The first thing to note is that high density foam isn’t a single entity, there are a multitude of different types of foam and therefore no single answer to the question of how to bond it successfully. So below we have created a guide to help.

Open Cell Foam

Open cell foam is a type of foam that is made up of flexible cells. These cells are connected to each other and are open to the surrounding environment. The open cell foam has almost a mesh like structure and is mostly empty space. This structure makes the foam breathable allowing air and moisture to pass through. It is also more resistant to mold and mildew and can be easily cut or shaped to fit any space. Consequently this type of foam is often used in upholstery.

In order to adhere to this type of foam we would recommend using a spray adhesive with an excellent adhesion that that sits on the top of the foam rather than using a brushable product that will sink into the holes. For a hard bond line we stock Heavy Duty Contact Adhesive Spray – M1600 which is a hand held easy to apply sprayable contact adhesive which is commonly used in upholstery. For a soft bond line again, we would suggest a sprayable product Sprayable Foam Contact Adhesive – C8530 which can be sprayed by hand and is also suited to upholstery applications.

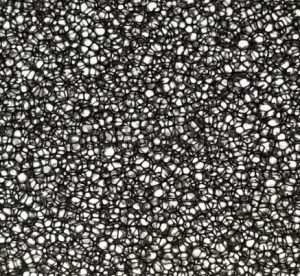

Closed Cell Foam

Closed cell foam is a type of foam that is made up of cells that are completely sealed off and not connected to each other. This means that no air or water can pass through the foam, making it an excellent choice for waterproofing and insulation. Closed cell foam is also more durable and resistant to abrasion than open cell foam, making it a great choice for high-impact applications. This type of foam is often used for outdoor applications due to it’s waterproof nature.

To adhere a closed cell type of foam (like neoprene) it depends on the application as to what we would recommend. If it needs to be waterproof such as for wetsuits or outdoor applications then our Contact Rubber Adhesive Kit – C5004 is a two-part contact adhesive which creates a strong waterproof bond. For high temperature requirements ie. anything over 50°C then we would suggest our Non-Flammable Sprayable Contact – C5154 which has the added benefits of being non-flammable and sprayable. For applications where the foam needs to remain flexible, we would suggest Sprayable Foam Contact Adhesive – C8530 which can be applied as a single way stick but always works best applied to both surfaces.

Rigid Foam

Rigid foams are used in a wide range of applications including construction, appliances, packaging, industrial, and transportation. Rigid foams typically have heavier densities than flexible foams. They are light and stiff, and have mechanical properties that make them attractive for energy management and packaging, and for lightweight structural use.

To adhere a rigid type of foam (like insulation panels) we would suggest Non-Flammable Sprayable Contact – C5154 as a non-flammable product it makes it particularly suited to domestic and building applications, with a great coverage per litre it is perfect for large areas.

Polypropylene Foam

Foamed Polypropylene is an extruded foam with a closed cell structure. The good mechanical and thermal properties in combination with its relatively low weight, make this material suitable for a wide range of applications.

A polypropylene foam is an incredibly difficult surface to create a structural bond so the adhesive needs to be as tacky as possible so we would suggest Sprayable Foam Contact Adhesive – C8530; however, it is imperative to test this as it is a notoriously difficult material to bond.